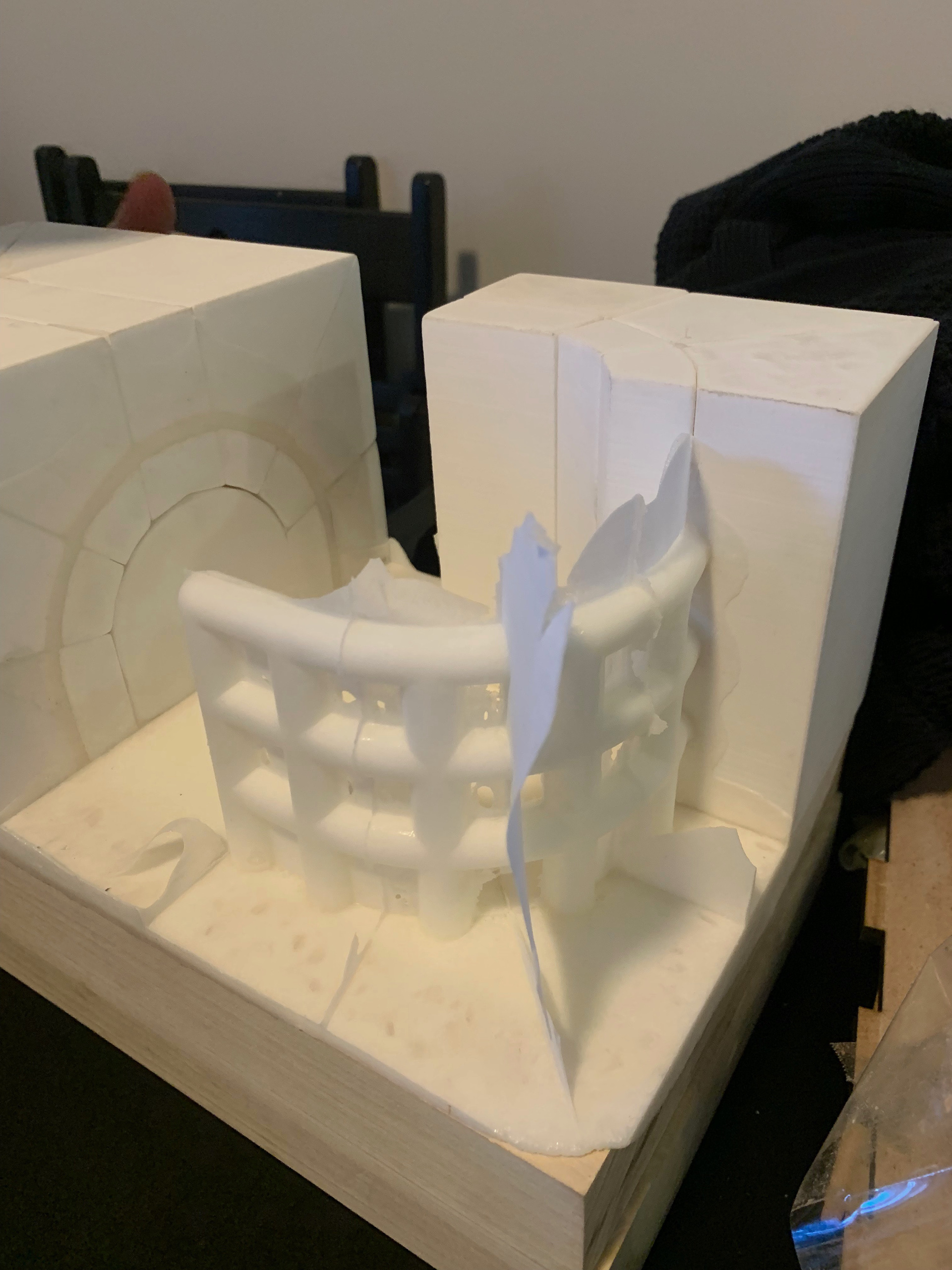

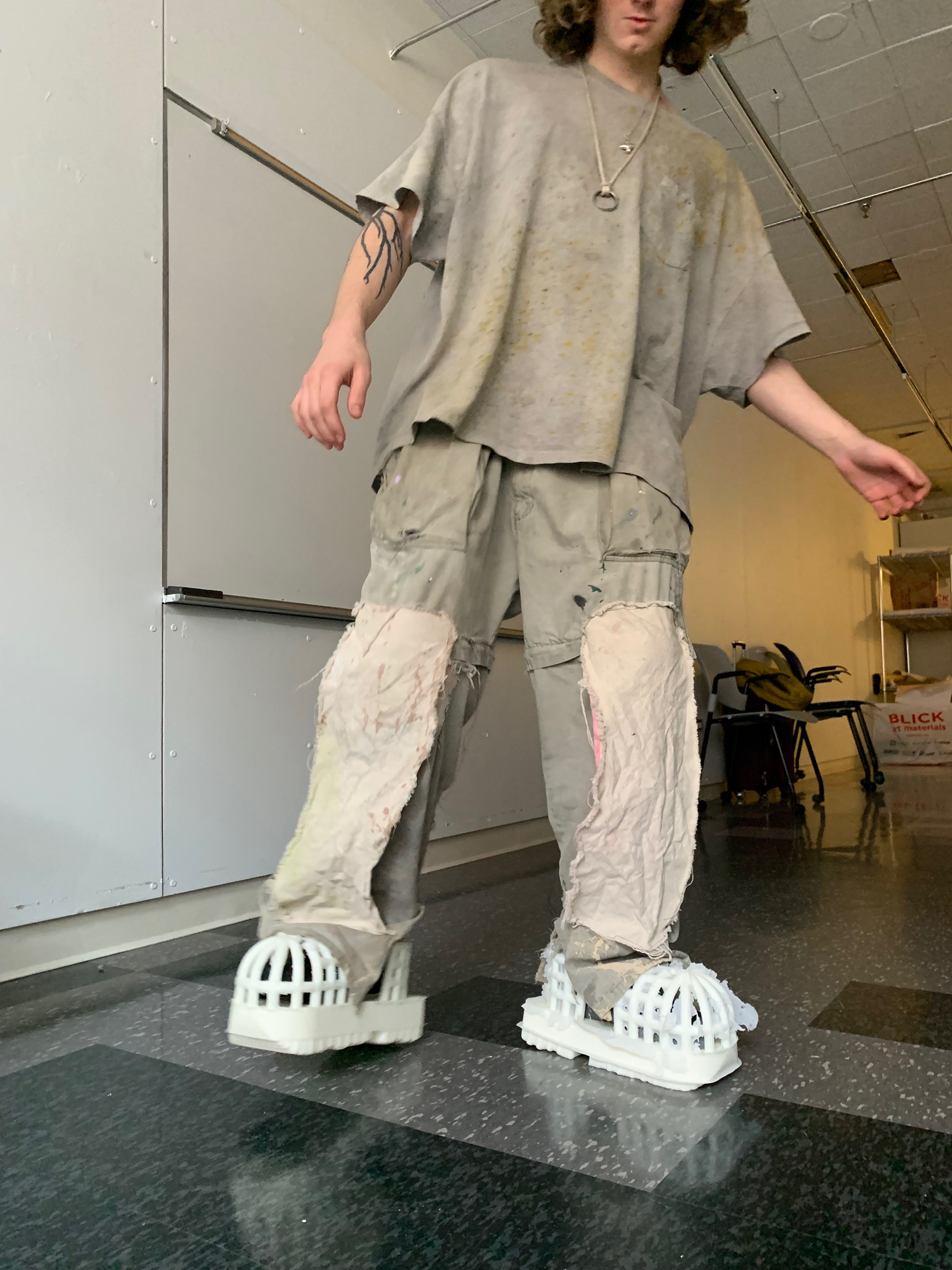

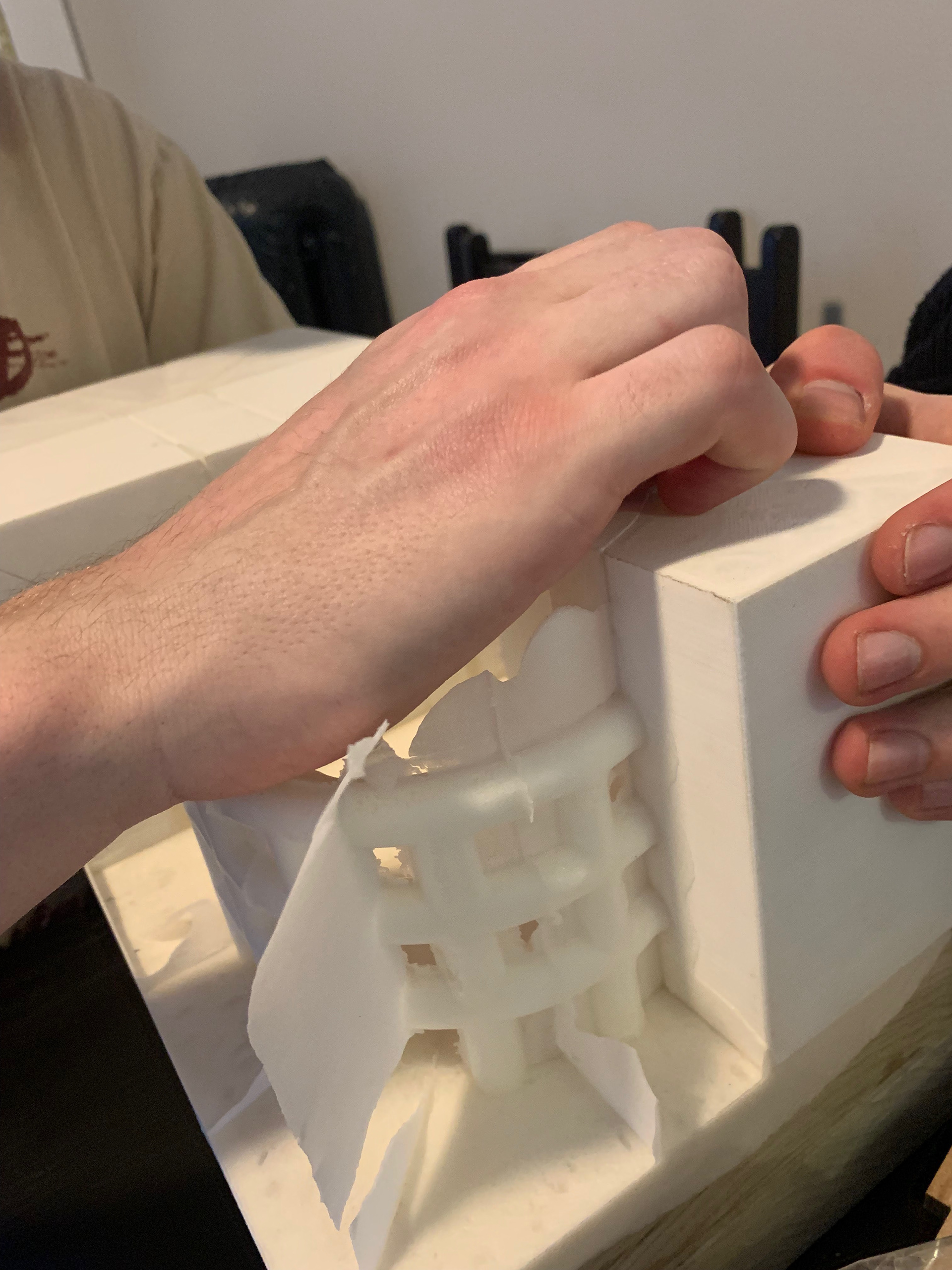

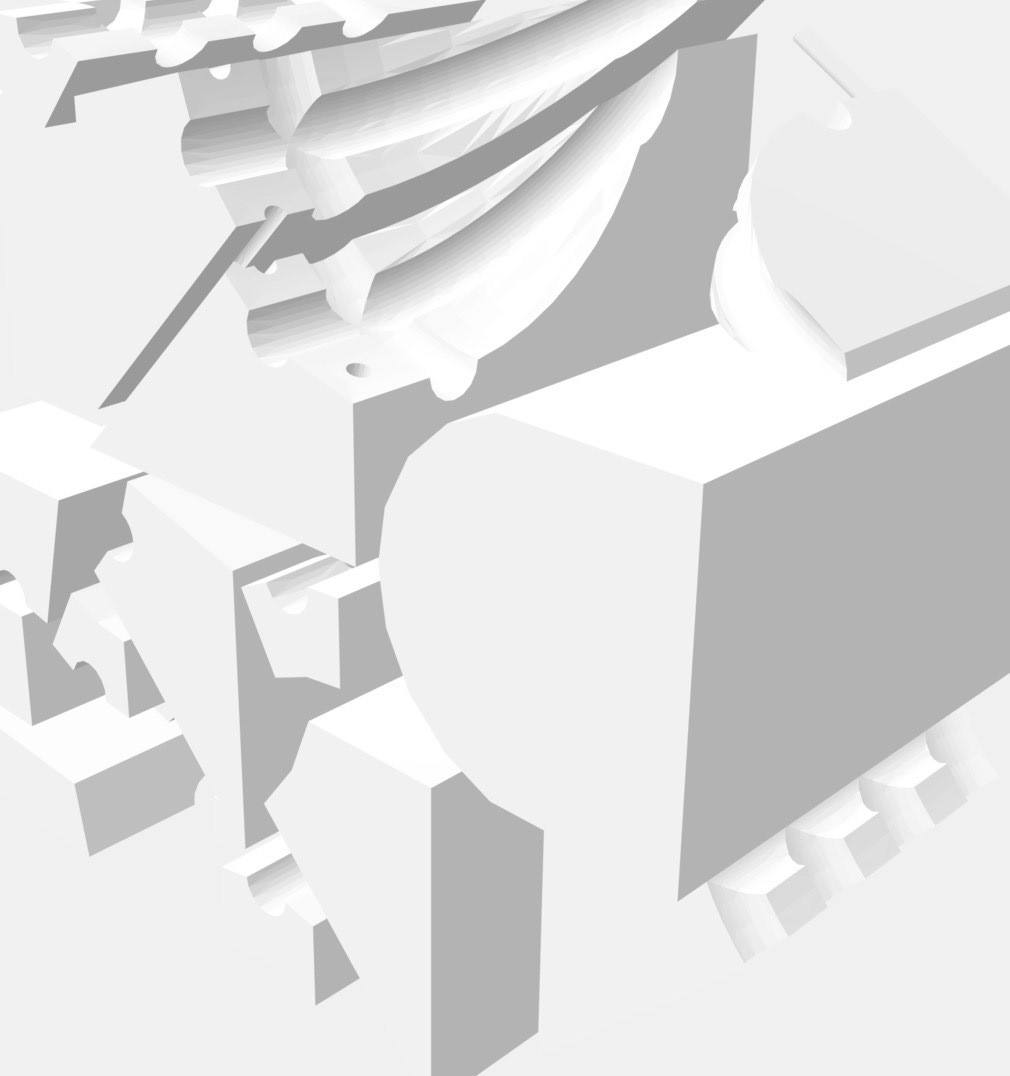

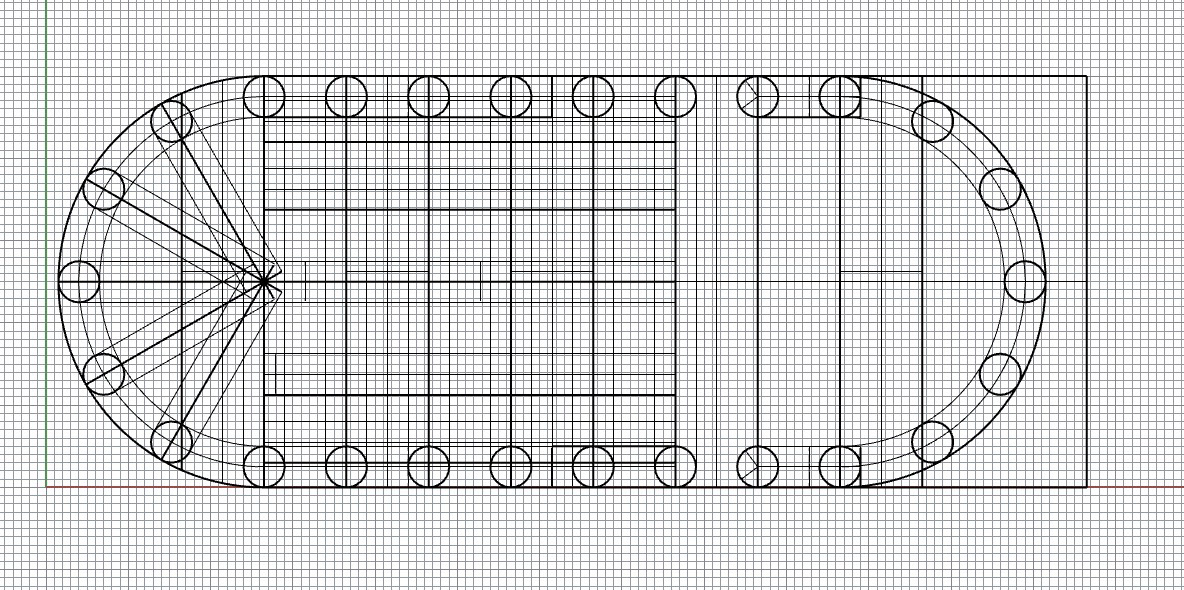

This prototype was created using an intricate process involving a mold with 2 CNC routed wood pieces, 12 laser-cut panels, and 42 3D printed components. Accentuated mold lines showcase the complexity of its creation. The geometrically intense grid form, intentionally deviating from the traditional foot shape, invites adaptation. The shoe is crafted to be hackable, allowing for elements to be woven into the grid boot for a personalized fit.

Here I use handwoven cloth filled will soft strips of foam to add comfort and personality to the boot.